| Coating thickness meter for measuring coatings on steel or non.ferrous metals |

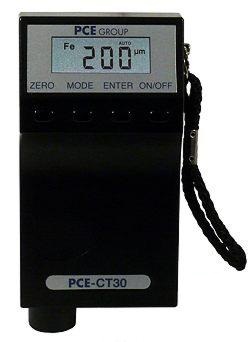

| The PCE-CT 30 coating thickness meter measures coating thickness on steel and non-ferrous metals without damaging the surface. The menu and adjustment for new parameters convert the PCE-CT 30 coating thickness meter into an indispensable device for testing during production, in workshops and in quality control. The ergonomical form of the coating thickness meter and its integrated sensor make it easy to use allowing for quick and accurate readings. It has been designed for measuring non-magnetic coatings such as lacquer, plastic, copper, chrome, zinc and enamel on steel and iron, as well as insulating coatings such as lacquer, plastic, enamel, paper, glass and rubber on copper, aluminium, brass, stainless steel and anodised aluminium. |

-

Instant measurement without the need to calibrate before hand. -

Wide measurement range from 0 to 3.5mm. -

Highly accurate. -

Can take continuous measurements. -

Measurements are not influenced by vibrations. -

Resistant to wear. -

The "V" slot simplifies measurements on curved surfaces such as axles. -

Optical alarm for measurements on unknown base materials. -

Comfortable to use in only one hand. -

Selectable units of measurement of either µm or mm. -

Turn on and off wither automatically or manually. -

Contents include coating thickness meter with battery, carrying case with calibration standard and user's manual. |  PCE-CT 30 coating thickness meter PCE-CT 30 coating thickness meter

View or print the user's manual

|

|

Here is the PCE-CT taking a measurement. |

| The coating thickness meter is used, above all, in the automotive industry. Who has bought a car that is supposedly never been in an accident, to later discover an area that has sustained major damage? It is not necessary to be an expert in materials, but it would be helpful to have the ability to determine if a car has been damaged and then repaired. The PCE-CT 30 coating thickness meter is the solution for easily determining the condition of body work on a car. Simple select the type of base material, either steel or aluminium, place the device on the area that you wish to measure and the reading will tell you if the coating of paint is uniform and to the correct thickness as applied originally by the manufacturer. In cases where body filler has been used, the coating on the metal will be more than one millimeter. The PCE-CT 30 coating thickness meter hs a range of 0 to 3500 µm (3.5mm). In cases where abnormal thickness are determined, it would be time to question the condition of the car and be more cautious.

The coating thickness meter can also be used in whichever industry where there is the need to measure the thickness of coatings on ferrous or non-ferrous materials. An example of this is galvanizing. To ensure that the coating thickness meter is showing the correct reading, there is a calibration standard included with the device. An optional ISO calibration can be ordered to ensure readings meet ISO standards. The certificate includes the measurement values and the serial number of the device. There is also a testing plate that will help determine when a recalibration is required. |

| Technical specifications |

| Measurement range | 0 to 3500 µm respectively 0 to 140 mils (selectable) |

| Measurement values | from 0.0 to 999 µm

from 1.00 to 3.50mm |

| Merter | ferrous and non-ferrous surfaces |

| Resolution | 0.1 µm in the range 0.0 to 99.9 µm

1 µm in the range 100 to 999 µm

0.01 mm in the range 1.00 to 3.50 mm

respectively

0.01 mils in the range 0.00 to 9.99 mils

0.1 mils in the range 10.0 to 99.0 mils

1.0 in the range 100 to 140 mils |

| Accuracy of repeat measurements | ±(1µm +2%) of 0 to 999 µm

±3.5% of 1001 to 3500 µm |

| Minimum area of measurement | 10 x 10mm |

| Minimal radial curvature | convexed: 5 mm; concaved: 30mm |

| Minimum base material thickness | type F: 0.2mm

type N: 0.05mm |

| Display | LCD with 4 digits |

| Operating temperature | 0 to 60°C |

| Power | 9V battery (included) |

| Dimensions | 118 x 58 x 38mm |

| Weight | 150g with battery |

| Contents

PCE-CT 30 coating thickness meter with integrated sensor, carrying case with calibration standard, battery and user's manual |

PCE-CT 30 coating thickness meter

PCE-CT 30 coating thickness meter